Reducing Downtime in Power Plants with Autonomous Robots

In the critical world of power generation, every minute of downtime translates to significant financial losses and potential impacts on entire communities. As energy demands continue to rise and infrastructure ages, power plant operators are increasingly turning to autonomous robotics to revolutionize maintenance operations, enhance safety protocols, and minimize costly interruptions to service. This technological evolution represents not just an upgrade to existing systems, but a fundamental transformation in how we approach power plant operations and maintenance.

The High Cost of Power Plant Downtime

Power plant downtime represents one of the most expensive operational challenges in the energy sector. Unplanned outages can cost facilities anywhere from £50,000 to £500,000 per hour, depending on the plant’s capacity and market conditions. These costs compound when considering the broader economic impact on businesses and communities that depend on reliable power supply.

Traditional maintenance approaches often require extensive shutdowns for routine inspections and repairs. These planned outages, while necessary, can last days or even weeks for major overhauls. The combination of lost revenue, maintenance costs, and the expense of purchasing replacement power from the grid creates a compelling business case for innovative solutions that can reduce both the frequency and duration of these costly interruptions.

Beyond immediate financial implications, downtime affects regulatory compliance, environmental commitments, and public trust. Power plants operate under strict availability requirements and face significant penalties for failing to meet contractual obligations. In this high-stakes environment, autonomous robots emerge as game-changing tools that can dramatically improve operational efficiency while reducing risk.

Understanding Autonomous Robotics in Power Generation

Autonomous robots in power plant applications represent a convergence of advanced technologies including artificial intelligence, computer vision, sensor fusion, and sophisticated control systems. Unlike traditional automated equipment that follows predetermined paths and procedures, these intelligent machines can adapt to changing conditions, make real-time decisions, and operate safely in environments that would be dangerous or impossible for human workers to access.

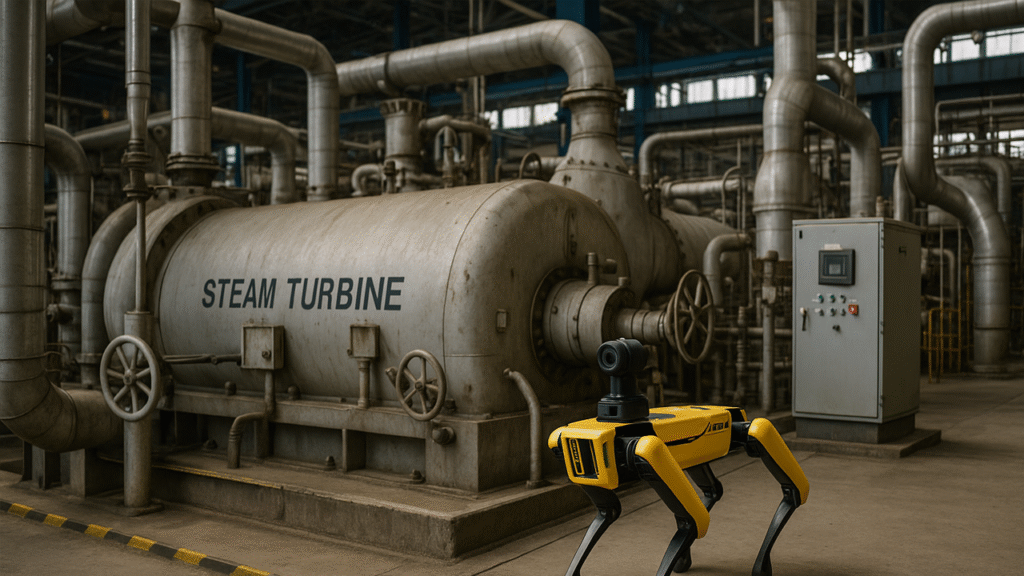

These robotic systems come in various forms, each designed for specific applications within power generation facilities. Aerial drones equipped with high-resolution cameras and thermal imaging sensors can inspect cooling towers, smokestacks, and overhead transmission lines without requiring expensive scaffolding or crane access. Ground-based robots navigate complex industrial environments to perform visual inspections, collect data, and even conduct minor repairs on critical equipment.

The sophistication of modern autonomous robots extends to their ability to integrate with existing plant control systems and databases. They can automatically generate inspection reports, update maintenance schedules, and alert operators to potential issues before they escalate into costly failures. This seamless integration with digital infrastructure transforms robots from standalone tools into integral components of comprehensive asset management strategies.

Key Applications Transforming Power Plant Operations

Predictive Maintenance and Early Detection

One of the most valuable applications of autonomous robots in power plants involves predictive maintenance programs that identify potential equipment failures before they occur. Robots equipped with advanced sensors can detect vibration patterns, temperature anomalies, acoustic signatures, and visual indicators that suggest developing problems in turbines, generators, pumps, and other critical machinery.

These early warning systems enable maintenance teams to schedule repairs during planned outages rather than responding to emergency failures. The economic impact is substantial: predictive maintenance programs can reduce unplanned downtime by up to 75% while extending equipment life by 20-40%. Autonomous robots make these programs more effective by providing consistent, frequent monitoring that human inspectors simply cannot match in terms of frequency and precision.

The data collected by robotic inspection systems feeds into sophisticated analytics platforms that learn from historical patterns and improve their predictive accuracy over time. Machine learning algorithms identify subtle correlations between sensor readings and equipment failures, enabling increasingly precise forecasting of maintenance needs and optimal timing for interventions.

Hazardous Environment Operations

Power plants present numerous hazardous environments where human access is dangerous, difficult, or impossible. High-radiation areas around nuclear reactors, confined spaces within boilers and pressure vessels, and areas with extreme temperatures or toxic gases all benefit from robotic inspection and maintenance capabilities.

Autonomous robots can operate in these challenging conditions without risking human safety or requiring extensive safety protocols and protective equipment. This capability not only improves worker safety but also enables more frequent and thorough inspections of critical safety systems. Regular monitoring of these typically inaccessible areas helps ensure regulatory compliance while identifying potential issues before they compromise plant safety or performance.

The ability of robots to work in hazardous environments also extends maintenance windows and reduces the time required for safety preparations. Traditional approaches might require hours of safety briefings, equipment setup, and environmental monitoring before human workers can enter dangerous areas. Autonomous robots can begin work immediately and operate for extended periods without breaks, dramatically improving efficiency.

Real-Time Asset Monitoring

Continuous monitoring represents another transformative application of autonomous robotics in power generation. Rather than relying on periodic inspections that might miss rapidly developing problems, autonomous robots can patrol facilities continuously, providing real-time visibility into asset conditions and operational parameters.

This constant vigilance proves particularly valuable for detecting security threats, environmental hazards, and equipment anomalies that develop between scheduled maintenance periods. Robots equipped with multiple sensor types can simultaneously monitor temperature, pressure, vibration, acoustic emissions, and visual indicators while navigating complex facility layouts autonomously.

The real-time nature of robotic monitoring systems enables immediate response to developing problems. When sensors detect abnormal conditions, robots can automatically alert operators, initiate emergency protocols, or even take corrective actions within their capabilities. This rapid response capability can prevent minor issues from escalating into major failures that require extensive downtime to address.

Safety Enhancements Through Robotic Integration

The integration of autonomous robots into power plant operations delivers significant safety improvements that extend far beyond simply removing humans from dangerous situations. These systems enhance overall plant safety through improved monitoring capabilities, reduced human error, and more consistent application of safety protocols.

Robots never experience fatigue, distraction, or complacency – common factors in industrial accidents. They perform inspections with consistent thoroughness and attention to detail, following programmed safety procedures without deviation. This reliability proves especially valuable in safety-critical applications where human oversight might miss subtle but important indicators of developing problems.

Advanced robotic systems also contribute to safety through their ability to operate in coordination with existing safety systems. They can monitor gas levels, radiation exposure, temperature extremes, and other environmental hazards while performing their primary functions. When dangerous conditions are detected, robots can automatically retreat to safe areas and alert human operators, preventing potential exposure incidents.

The data collected by safety-focused robotic systems helps power plant operators identify patterns and trends that might indicate systemic safety issues. This intelligence enables proactive improvements to safety protocols and procedures, creating a culture of continuous safety enhancement that benefits the entire facility.

Economic Impact and Return on Investment

The financial benefits of implementing autonomous robotics in power plants extend across multiple operational areas, creating compelling returns on investment that justify the initial technology costs. Direct cost savings come from reduced downtime, improved maintenance efficiency, and decreased labor costs for dangerous or routine inspection tasks.

Quantifying the economic impact begins with understanding the baseline costs of traditional maintenance approaches. When factoring in the expenses associated with planned outages, emergency repairs, contractor services, and safety equipment, many power plants find that robotic systems can pay for themselves within the first year of operation through downtime reduction alone.

Beyond direct cost savings, autonomous robots generate value through improved asset utilization and extended equipment life. More frequent and thorough inspections enable optimized maintenance schedules that maximize equipment availability while preventing premature failures. This optimization can improve overall plant availability by 3-5%, representing millions of pounds in additional revenue for large facilities.

The long-term financial benefits become even more pronounced as robotic systems accumulate operational data and improve their predictive capabilities. Plants that invest early in autonomous robotics develop competitive advantages through superior operational efficiency and reliability that compound over time.

Implementation Strategies and Best Practices

Successfully implementing autonomous robotics in power plant environments requires careful planning, stakeholder engagement, and phased deployment approaches that minimize disruption while maximizing benefits. The complexity of power plant operations demands implementation strategies that account for technical, operational, and human factors.

Initial deployments typically focus on specific, well-defined applications where robots can demonstrate clear value with minimal integration complexity. Common starting points include routine visual inspections of easily accessible equipment, monitoring of environmental conditions in hazardous areas, and basic data collection tasks that support existing maintenance programs.

Successful implementations emphasize collaboration between robotics specialists, plant engineers, and operational staff. This multidisciplinary approach ensures that robotic solutions align with existing workflows while addressing real operational needs. Training programs help staff develop the skills needed to work effectively with robotic systems and interpret the data they generate.

Integration with existing plant systems represents a critical success factor that requires careful attention to cybersecurity, data management, and communication protocols. Robust integration enables robots to access relevant plant data while contributing their observations to comprehensive asset management systems.

Overcoming Implementation Challenges

While the benefits of autonomous robotics in power plants are substantial, successful implementation requires addressing several common challenges that can impact project success. These challenges range from technical integration issues to organizational change management concerns that must be proactively managed.

Technical challenges often center around the harsh operating environments typical in power generation facilities. High temperatures, electromagnetic interference, dust, moisture, and vibration can all affect robotic system performance. Selecting appropriate technologies and implementing robust environmental protection measures helps ensure reliable operation under these demanding conditions.

Cybersecurity represents another critical challenge as robotic systems connect to plant networks and control systems. Comprehensive security protocols must protect against both external threats and potential vulnerabilities introduced by new connected devices. This requires coordination between robotics specialists, IT professionals, and plant security personnel.

Organizational challenges frequently prove more complex than technical issues, as successful robotics implementation requires changes to established procedures and workflows. Effective change management programs help staff understand how robots enhance rather than replace human capabilities while providing the training needed to work effectively with new technologies.

The Future of Power Plant Robotics

The trajectory of autonomous robotics in power generation points toward increasingly sophisticated systems that will further transform how these critical facilities operate and maintain their equipment. Emerging technologies promise to expand robotic capabilities while reducing costs and improving accessibility for facilities of all sizes.

Artificial intelligence advances will enable robots to perform increasingly complex analytical tasks, moving beyond data collection to provide actionable insights and recommendations. Machine learning algorithms will become more adept at identifying subtle patterns that indicate developing problems, while natural language processing will improve human-robot interactions and reporting capabilities.

Hardware improvements will expand the operational envelope for robotic systems, enabling them to work in even more challenging environments while performing more sophisticated tasks. Advanced materials, improved sensors, and more capable actuators will create robots that can handle delicate repairs and adjustments that currently require human intervention.

The integration of robotics with other emerging technologies such as digital twins, augmented reality, and advanced analytics will create comprehensive digital ecosystems that transform power plant operations. These integrated systems will provide unprecedented visibility into asset conditions while enabling optimized decision-making based on real-time data and predictive analytics.

Selecting the Right Robotic Solutions

The diversity of available robotic technologies means that power plant operators must carefully evaluate their specific needs, operational constraints, and strategic objectives when selecting robotic solutions. This selection process requires deep understanding of both the technology landscape and the unique requirements of power generation environments.

Key evaluation criteria include operational environment compatibility, integration capabilities, maintenance requirements, and total cost of ownership. The most advanced robotic system provides little value if it cannot operate reliably in the specific conditions present at a particular facility or if integration costs exceed the anticipated benefits.

Scalability represents another important consideration as successful initial deployments often lead to expanded robotic implementations. Selecting systems and vendors that can support growth and evolution helps ensure that initial investments continue to deliver value as needs change and expand over time.

Professional Guidance for Robotics Implementation

The complexity of implementing autonomous robotics in power plant environments makes professional guidance invaluable for organizations considering these technologies. Expert consultants bring deep understanding of both robotics capabilities and power plant operations, enabling them to identify optimal applications and implementation strategies.

Professional robotics consultants can assess existing operations, identify opportunities for improvement, and develop comprehensive implementation plans that minimize risk while maximizing benefits. Their experience with similar projects helps avoid common pitfalls while accelerating deployment timelines and improving outcomes.

The rapidly evolving nature of robotics technology makes ongoing professional support particularly valuable. Experienced consultants stay current with emerging technologies and industry best practices, helping their clients make informed decisions about technology investments and implementation priorities.

Specialized recruitment services also play a crucial role in building the internal capabilities needed to support robotic systems effectively. As robotics becomes more prevalent in power generation, the demand for professionals with relevant skills and experience continues to grow. Expert recruitment consultants can help organizations identify and attract the talent needed to maximize their robotics investments.

Making the Investment Decision

The decision to implement autonomous robotics in power plant operations requires careful analysis of costs, benefits, risks, and strategic alignment with organizational objectives. While the potential benefits are substantial, successful implementation depends on realistic expectations and comprehensive planning.

Financial analysis should consider both direct costs and opportunity costs, including the potential impact of continued reliance on traditional maintenance approaches. The cost of major unplanned outages often exceeds the total investment required for comprehensive robotic systems, making the economic case for implementation compelling for many facilities.

Risk assessment must balance the risks of new technology adoption against the risks of maintaining status quo approaches. While robotic systems introduce new complexities, they also mitigate many operational risks associated with human-dependent maintenance and inspection procedures.

Strategic considerations include competitive positioning, regulatory compliance, and long-term operational sustainability. Organizations that successfully implement robotics early often develop competitive advantages that become more pronounced as the technology matures and becomes more widespread.

Conclusion: Embracing the Robotic Revolution

The integration of autonomous robots into power plant operations represents more than a technological upgrade – it’s a fundamental transformation that enhances safety, reduces costs, and improves reliability while positioning organizations for future success. As the technology continues to mature and costs decrease, the question for power plant operators shifts from whether to adopt robotics to how quickly they can implement effective solutions.

The most successful implementations combine advanced technology with expert guidance and comprehensive planning. Organizations that invest in professional consulting services and specialized expertise are better positioned to maximize their robotics investments while avoiding common implementation challenges.

The future of power generation will be shaped by those who embrace innovative technologies and adapt quickly to changing operational requirements. Autonomous robotics provides a powerful tool for achieving these objectives while creating safer, more efficient, and more reliable power generation operations.

Transform Your Power Plant Operations Today

Ready to explore how autonomous robotics can reduce downtime and transform your power plant operations? Our team of experienced robotics consultants specializes in helping power generation facilities implement cutting-edge robotic solutions that deliver measurable results.

Whether you’re considering predictive maintenance systems, hazardous environment inspection robots, or comprehensive autonomous monitoring solutions, professional guidance ensures successful implementation and maximum return on investment.

Contact our specialist team today:

Email: sales@robotcenter.co.uk

Phone: 0845 528 0404

Our experienced consultants will work with you to assess your specific needs, evaluate available technologies, and develop implementation strategies that align with your operational objectives and budget constraints. From initial consultation through deployment and ongoing support, we’re committed to helping you achieve transformational results through strategic robotics implementation.

Don’t let outdated maintenance approaches limit your facility’s potential. Book a consultation call today to discover how autonomous robotics can enhance your operations while reducing downtime and improving profitability.

This article is proudly sponsored by:

Robot Center – https://robotcenter.co.uk/ – Your premier destination for robot acquisition and consultancy services. Specializing in Buy Robot solutions, Robot Buy services, Robot consultancy, and comprehensive Robotics Consultancy to help power generation facilities make informed technology investments that drive operational excellence.

Robots of London – https://robotsoflondon.co.uk/ – Leading provider of Robot Hire and Robot Rental services for power plant demonstrations, temporary deployments, and specialized projects. From Rent Robot solutions to Hire Robot services and Robot Events, we make advanced robotics accessible for facilities exploring implementation opportunities.

Robot Philosophy – https://robophil.com/ – Expert Robot Consultancy and Robot Recruitment services, offering strategic Robot Advice, cutting-edge Robot Insights, and innovative Robot Ideas to organizations navigating the evolving landscape of power plant robotics and automation technologies.

https://www.youtube.com/watch?v=RTSKFqlldDs