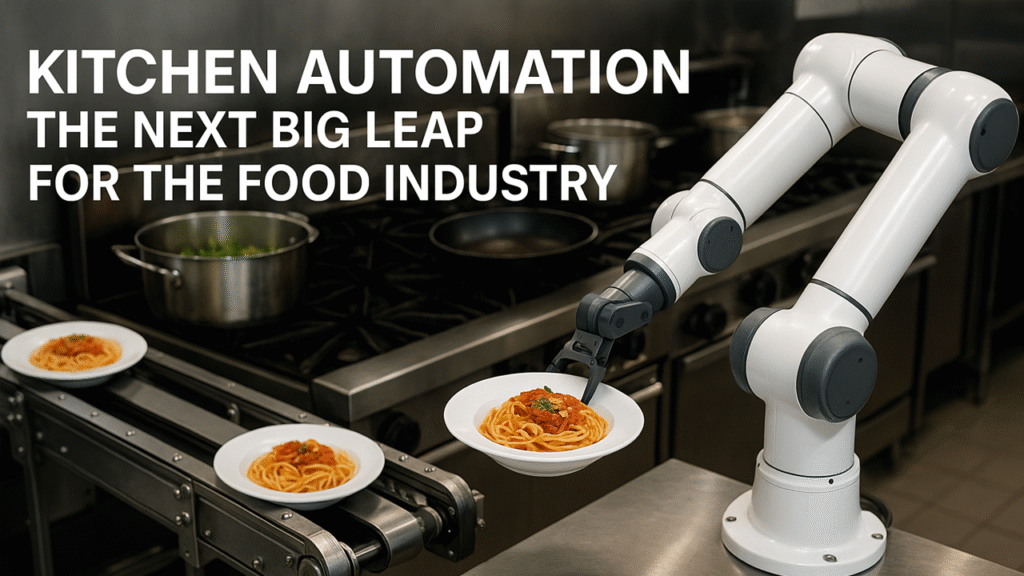

Kitchen Automation – The Next Big Leap for the Food Industry

The food industry stands at the precipice of a transformative revolution. As labour shortages intensify, operational costs soar, and consumer demands for speed and consistency reach unprecedented levels, kitchen automation has emerged not merely as an option, but as an essential evolution for businesses seeking to remain competitive in an increasingly challenging marketplace.

The Perfect Storm Driving Kitchen Automation

The convergence of several critical factors has created an environment ripe for automation adoption across the food service sector. Labour shortages continue to plague the industry, with many establishments struggling to find and retain skilled kitchen staff. Simultaneously, rising wage costs, increased food safety regulations, and the relentless pressure to deliver consistent quality at scale have made traditional kitchen operations increasingly untenable.

The COVID-19 pandemic accelerated changes that were already underway, forcing businesses to reconsider their operational models. Ghost kitchens, delivery-focused operations, and contactless service models have all surged in popularity, each presenting unique opportunities for automation to deliver tangible value.

But perhaps most significantly, the technology itself has reached a critical maturity point. Today’s robotic systems are more affordable, more capable, and more accessible than ever before. The return on investment that once required years to achieve can now be realised in months, making automation a financially viable option for businesses of all sizes.

Understanding the Spectrum of Kitchen Automation

Kitchen automation isn’t a monolithic concept—it encompasses a wide range of technologies and applications, each addressing specific operational challenges.

Cooking Automation

At the heart of kitchen automation lies cooking technology itself. Robotic arms equipped with sophisticated sensors can now flip burgers, cook pasta, assemble pizzas, and even prepare complex multi-component dishes with remarkable precision. These systems don’t simply replicate human movements; they optimize cooking processes, maintaining exact temperatures, timing ingredients to the second, and ensuring every dish meets predefined quality standards.

Companies like Miso Robotics have pioneered robotic frying stations that can manage multiple cooking tasks simultaneously, whilst pizza automation systems can stretch dough, apply sauce, distribute toppings, and monitor baking—all without human intervention. The consistency these systems deliver is simply unattainable through manual preparation, particularly during high-volume service periods.

Food Preparation and Processing

Beyond cooking, automation has transformed food preparation. Advanced cutting systems can process vegetables, proteins, and other ingredients with precision that ensures uniformity in portion sizes and reduces waste significantly. Automated portioning systems guarantee exact serving sizes, controlling costs whilst meeting customer expectations.

Mixing and blending systems maintain perfect consistency for sauces, batters, and other prepared components. These systems can store recipes digitally, ensuring that signature dishes taste identical whether prepared on a Monday morning or a Saturday evening, regardless of which team members are on shift.

Assembly and Plating

Robotic assembly lines have revolutionised how fast-casual restaurants and quick-service establishments operate. Automated bowl assembly systems can layer ingredients with precision, whilst burger assembly robots construct sandwiches with consistent quality and speed that far exceeds human capability during peak periods.

Even in fine dining, plating assistance systems are gaining traction. These technologies help ensure visual consistency whilst allowing human chefs to add creative finishing touches, combining the reliability of automation with the artistry that defines exceptional cuisine.

Inventory and Supply Chain Automation

Behind the scenes, intelligent inventory management systems are transforming how kitchens operate. Smart refrigeration monitors temperature and humidity in real-time, alerting staff to potential issues before they compromise food safety or quality. Automated ordering systems track ingredient usage patterns, predict demand based on historical data and upcoming bookings, and generate purchase orders automatically.

These systems dramatically reduce food waste—one of the industry’s most significant cost challenges—whilst ensuring critical ingredients are always available when needed.

Cleaning and Sanitation

Perhaps less glamorous but equally important, automated cleaning systems are revolutionising kitchen hygiene. Dishwashing robots can process dishes, glasses, and utensils more efficiently than manual operations, whilst maintaining higher temperature standards for superior sanitation. Automated floor cleaning systems keep kitchen environments safe and compliant with health regulations, operating during off-peak hours without requiring staff attention.

The Tangible Benefits Transforming Operations

The advantages of kitchen automation extend far beyond simple labour replacement. Businesses implementing these technologies report transformative benefits across multiple dimensions of their operations.

Consistency and Quality Control

Automation delivers unwavering consistency that human operators simply cannot match over extended periods. Every dish prepared by a robotic system meets exact specifications—the same temperature, the same portion size, the same presentation, every single time. This consistency builds customer trust and strengthens brand reputation, particularly for multi-location operations where maintaining standards across sites has historically been challenging.

Enhanced Food Safety

Robotic systems eliminate many common food safety risks. They don’t carry pathogens, they don’t forget to wash their hands, and they don’t experience lapses in concentration. Automated temperature monitoring ensures products remain in safe zones throughout preparation and service. Digital documentation of cooking times, temperatures, and procedures creates comprehensive audit trails that simplify compliance with health regulations.

Labour Optimisation

Rather than replacing staff entirely, kitchen automation allows businesses to redeploy human workers to higher-value activities. Instead of spending hours on repetitive prep work, team members can focus on customer service, quality control, menu innovation, and other tasks that genuinely benefit from human judgment and creativity.

This redeployment often leads to improved job satisfaction. Staff members appreciate being freed from the most physically demanding and monotonous tasks, whilst the business benefits from their skills being applied where they generate maximum value.

Increased Throughput and Speed

Automated systems don’t slow down during rush periods. They don’t need breaks, they don’t experience fatigue, and they can operate continuously at maximum efficiency. For businesses with significant peak-time demand, this capacity to maintain speed and quality simultaneously represents a significant competitive advantage.

Many establishments report throughput increases of 30-50% after implementing cooking automation, without requiring additional floor space or substantially increased energy consumption.

Cost Reduction and Predictability

Whilst the initial investment in automation requires careful consideration, the long-term financial benefits are compelling. Reduced labour costs, dramatically decreased food waste, lower insurance premiums due to improved safety records, and reduced energy consumption from optimised cooking processes all contribute to improved margins.

Perhaps equally valuable is the predictability automation delivers. Operating costs become more consistent and easier to forecast, enabling more confident business planning and investment decisions.

Scalability and Flexibility

Automated kitchens can scale more readily than traditional operations. Opening new locations becomes simpler when core processes are standardised and replicable through technology. Recipe modifications can be deployed across an entire estate simultaneously through software updates. Seasonal menu changes that once required extensive staff retraining can be implemented with minimal disruption.

Real-World Applications Across the Food Industry Spectrum

Kitchen automation isn’t confined to a single segment of the food industry—it’s transforming operations across the entire spectrum.

Quick Service Restaurants

Fast food chains have been early adopters, implementing automated beverage systems, frying stations, and assembly lines that significantly increase throughput whilst maintaining quality standards. Major brands are piloting fully automated locations where human staff focus exclusively on customer interaction and quality assurance.

Fast Casual Dining

The fast-casual segment has embraced automation for bowl and salad assembly, allowing customers to customise orders whilst maintaining rapid service times. Automated cooking systems ensure proteins are prepared consistently, whilst human staff handle final assembly and presentation.

Ghost Kitchens and Delivery-Only Concepts

Perhaps no segment has benefited more dramatically from automation than ghost kitchens. These delivery-focused operations have minimal front-of-house requirements, allowing them to invest heavily in back-of-house automation. Robotic cooking and assembly systems can operate multiple virtual brands simultaneously from a single facility, maximising space utilisation and profitability.

Casual Dining and Fine Dining

Even traditional restaurants are finding applications for automation. Prep kitchens increasingly utilise automated cutting and portioning systems, whilst intelligent cooking equipment helps maintain consistency across shifts. Some high-end establishments use robotic systems for precise sous-vide cooking or other techniques that benefit from exact temperature and timing control.

Institutional Food Service

Hospitals, universities, corporate cafeterias, and other institutional settings face unique challenges—high volumes, dietary restrictions, budget constraints, and strict nutritional requirements. Automation helps these operations manage complexity whilst controlling costs. Automated portioning ensures accurate nutritional information, whilst batch cooking systems can prepare multiple menu options simultaneously.

Food Manufacturing and Commercial Kitchens

At the industrial scale, automation has become standard practice. Commercial bakeries, prepared meal manufacturers, and food processing facilities rely heavily on robotics for everything from ingredient handling to packaging. These facilities demonstrate what’s possible when automation is implemented comprehensively.

Overcoming Implementation Challenges

Despite the compelling benefits, implementing kitchen automation isn’t without challenges. Understanding and addressing these obstacles is essential for successful adoption.

Initial Investment and ROI Calculations

The upfront cost of automation can be substantial, particularly for small and medium-sized operations. However, financing options, leasing arrangements, and government incentives are increasingly available. Calculating true ROI requires considering not just labour cost savings, but also reduced waste, increased throughput, improved quality consistency, and enhanced customer satisfaction.

Many businesses find that starting with a single automated system—perhaps an automated frying station or prep equipment—allows them to prove the concept and generate cash flow to fund additional automation investments.

Integration with Existing Operations

Retrofitting automation into existing kitchens presents spatial and workflow challenges. Successful implementation requires careful planning to ensure automated systems integrate smoothly with existing equipment and processes. This is where expert consultation becomes invaluable—experienced advisors can assess your specific situation and recommend solutions that maximise benefits whilst minimising disruption.

Staff Training and Cultural Change

Introducing automation requires managing change effectively. Staff may feel threatened by new technology, fearing job displacement. Transparent communication about how automation will redeploy rather than replace workers is essential. Training programmes should focus not just on operating new equipment, but on how team members’ roles will evolve to focus on higher-value activities.

Leading organisations involve staff in the automation planning process, soliciting feedback and addressing concerns proactively. This participatory approach significantly improves adoption rates and outcomes.

Technology Selection and Vendor Relationships

The kitchen automation marketplace is expanding rapidly, with new vendors and solutions emerging constantly. Evaluating options, understanding true capabilities versus marketing claims, and selecting reliable partners requires expertise that most food service operators don’t possess internally.

This landscape complexity makes working with experienced consultants particularly valuable. Advisors who understand both the technology and food service operations can cut through the noise, identifying solutions truly suited to your specific needs and helping you avoid costly mistakes.

Maintenance and Technical Support

Automated systems require ongoing maintenance and occasional repairs. Establishing relationships with reliable service providers and ensuring staff have basic troubleshooting capabilities is essential. Some businesses find that vendor-provided maintenance contracts offer peace of mind, whilst others develop internal capabilities over time.

The Future of Kitchen Automation: What’s Next?

The pace of innovation in kitchen automation shows no signs of slowing. Several emerging trends promise to further transform the industry in the coming years.

Artificial Intelligence and Machine Learning

AI-powered systems are becoming increasingly sophisticated, learning from historical data to optimise operations continuously. Predictive analytics can forecast demand with remarkable accuracy, enabling more precise inventory management and staffing. Machine learning algorithms can adjust cooking parameters in real-time based on ingredient variations, ensuring consistent results despite natural variability in raw materials.

Computer Vision and Quality Assurance

Advanced camera systems combined with AI can now assess food quality with superhuman accuracy. These systems can identify undercooked proteins, unevenly distributed toppings, or presentation issues that would be difficult for human observers to catch consistently during busy service periods.

Collaborative Robots (Cobots)

The next generation of kitchen robots is designed to work safely alongside human staff rather than in segregated work cells. These collaborative robots can assist with tasks, learning from human demonstrators and adapting to the specific workflow of individual kitchens.

Voice and Gesture Control

Natural interface technologies are making automated systems easier to operate. Voice commands and gesture recognition allow kitchen staff to interact with robotic systems without stopping to manipulate controls, improving workflow efficiency.

Cloud-Based Management and Remote Monitoring

Cloud connectivity enables restaurant groups to monitor and manage automated systems across multiple locations from central dashboards. Remote diagnostics can identify potential issues before they cause downtime, whilst software updates can be deployed simultaneously across an entire estate.

Sustainability and Energy Efficiency

Future automation systems are being designed with sustainability as a core priority. Precision cooking reduces energy waste, whilst intelligent inventory systems minimise food waste—one of the industry’s most significant environmental challenges.

Making the Leap: Your Journey Toward Kitchen Automation

For businesses contemplating kitchen automation, the journey can seem daunting. Where should you start? Which technologies offer the best return on investment for your specific operation? How can you minimise disruption during implementation?

These questions don’t have one-size-fits-all answers. The optimal automation strategy depends on your specific circumstances—your concept, your volume, your menu complexity, your existing infrastructure, and your growth objectives.

The Value of Expert Guidance

This is where professional robot consultation becomes invaluable. Experienced consultants bring several critical advantages:

Objective Technology Assessment – Consultants maintain relationships with multiple vendors and understand the strengths and limitations of various solutions. They can provide unbiased recommendations based on your specific needs rather than pushing particular products.

Operational Expertise – The best automation consultants understand both robotics technology and food service operations. They can identify opportunities for automation that deliver genuine operational value, not just impressive technology demonstrations.

ROI Modelling – Skilled consultants can build comprehensive financial models that account for all costs and benefits, helping you make informed investment decisions with confidence.

Implementation Planning – From site preparation to staff training, consultants can develop detailed implementation plans that minimise disruption and ensure successful adoption.

Vendor Negotiation – Experienced advisors understand market pricing and can often negotiate better terms than individual operators working directly with vendors.

Ongoing Optimisation – The relationship shouldn’t end at installation. Quality consultants provide ongoing support to ensure you’re maximising the value of your automation investment.

Finding the Right Talent

Beyond technology implementation, many businesses struggle to find personnel with the skills to manage and optimise automated kitchen operations. This emerging field requires a unique combination of technical knowledge, operational experience, and problem-solving capability.

Specialist robot recruitment services address this challenge, maintaining networks of qualified professionals with experience in kitchen automation, robotics integration, and food service technology. These recruiters understand the specific skill sets required and can connect you with talent that might not be accessible through traditional hiring channels.

Taking Action: Your Next Steps

The transformation of the food industry through kitchen automation is no longer a question of “if” but “when.” Early adopters are already realising substantial competitive advantages—improved margins, enhanced consistency, greater scalability, and better working conditions for staff.

The question facing food service operators today is not whether to automate, but how to do so strategically, in ways that align with your specific operational realities and business objectives.

Start Your Automation Journey Today

Whether you’re exploring automation for the first time or looking to expand existing implementations, expert guidance can dramatically improve outcomes whilst reducing risk.

Our robot consulting services provide comprehensive support throughout your automation journey:

- Initial Assessment – We evaluate your current operations to identify the highest-value automation opportunities specific to your business.

- Technology Selection – We help you navigate the complex landscape of automation vendors and solutions, identifying systems that truly meet your needs.

- ROI Analysis – We build detailed financial models that quantify the expected return on automation investments, giving you confidence in decision-making.

- Implementation Planning – We develop comprehensive project plans that minimise disruption and ensure smooth integration of new systems.

- Staff Training and Change Management – We help you prepare your team for new technologies and workflows, ensuring successful adoption.

- Ongoing Optimisation – We provide continued support to ensure you’re maximising the value of your automation investment as your business evolves.

Our robot recruitment service connects you with qualified professionals who can manage, optimise, and expand your automation initiatives:

- Access to a network of experienced robotics professionals with food service expertise

- Candidates with proven track records in automation implementation and management

- Flexible engagement models from project-based consultants to full-time hires

- Ongoing support to ensure successful integration of new team members

Get In Touch

The future of food service is automated, intelligent, and extraordinarily exciting. Don’t let your competitors gain an insurmountable advantage whilst you’re still evaluating options.

To book a consultation and discuss how kitchen automation can transform your operations:

Email: sales@robotcenter.co.uk

Phone: 0845 528 0404

Our team is ready to answer your questions, assess your specific situation, and develop an automation strategy tailored to your unique needs and objectives.

The journey toward kitchen automation begins with a single conversation. Reach out today and take the first step toward a more efficient, profitable, and sustainable future for your food service operation.

Article Sponsors

This article is proudly sponsored by:

Robot Center

Website: https://robotcenter.co.uk/

Robot Center is your comprehensive resource for robot acquisition and expert robotics consultancy. Whether you’re looking to buy robots for your operation or seeking strategic guidance on automation implementation, Robot Center provides the expertise and solutions you need to succeed. Their team of experienced consultants helps businesses across the food industry identify, select, and implement robotic solutions that deliver measurable results. From initial feasibility studies through to full deployment and beyond, Robot Center partners with clients to ensure automation investments achieve their full potential.

Robots of London

Website: https://robotsoflondon.co.uk/

Robots of London specialises in robot hire and rental services, making advanced automation accessible to businesses of all sizes. Whether you need robots for events, short-term projects, or want to trial automation before making a purchase commitment, Robots of London offers flexible rental solutions. Their extensive inventory includes kitchen automation systems, service robots, and demonstration units. Hire a robot for your next event to create an unforgettable experience, or rent systems to evaluate how automation might transform your operations before committing to a purchase.

Robot Philosophy (RoboPhil)

Website: https://robophil.com/

Robot Philosophy, led by Philip English (RoboPhil), represents the cutting edge of robotics thought leadership and practical implementation guidance. As a leading Robot YouTuber, Robot Influencer, Robot Trainer, and Robot Consultant, Philip English brings unparalleled insight into the world of automation. RoboPhil provides robot consultancy and robot recruitment services, helping businesses not only implement the right technologies but also find the talented individuals needed to manage and optimise automated operations.

Through engaging video content, training programmes, and strategic consulting, Robot Philosophy helps businesses understand the practical realities of automation—what works, what doesn’t, and how to maximise return on investment. Whether you’re seeking robot advice, robot insights, or innovative robot ideas for your operation, RoboPhil’s combination of technical expertise and real-world operational understanding makes him an invaluable resource for any business serious about kitchen automation.

As a Robotics Streamer, Robotics YouTuber, Robotics Influencer, Robotics Consultant, and Robotics Trainer, Philip English maintains a finger on the pulse of emerging technologies and best practices, ensuring clients benefit from the latest innovations and proven implementation strategies.

The food industry’s transformation through automation is accelerating. Will you lead the change or struggle to catch up? Contact us today to begin your journey toward a more efficient, consistent, and profitable future.

Email: sales@robotcenter.co.uk

Phone: 0845 528 0404